In Situ Crankshaft Grinding: A Cost-Effective Solution by RA Power Solutions | Crankshaft Grinding Machine

In the world of heavy machinery, engines are the heart that keeps operations running smoothly. However, over time, even the most robust engines can develop issues, particularly with their crankshafts. Crankshafts are critical components that convert linear motion into rotational motion, and any damage can lead to significant downtime and costs.

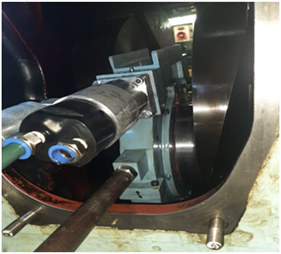

Traditionally, when a crankshaft developed issues like wear, deformation, or even cracks, the only solution was to replace it entirely or undertake expensive repairs involving dismantling the engine. However, with advancements in technology, a more cost-effective and efficient solution has emerged: In Situ Crankshaft Grinding.

Advantages of In Situ Crankshaft Grinding

Cost-Effective: In Situ grinding eliminates the need to remove and transport the crankshaft to a workshop, reducing downtime and costs significantly.

Time-Saving: The entire process can be completed in a fraction of the time required for traditional repairs, minimizing downtime and operational losses.

Call us at +91 9582647131 or +91 9810012383.

Quality Assurance: The process is carried out by skilled technicians using specialized equipment, ensuring high-quality repairs that meet or exceed OEM standards.

Environmentally Friendly: In situ grinding reduces the carbon footprint associated with transporting and processing damaged crankshafts.

RA Power Solutions: A Leader in In Situ Crankshaft Grinding

RA Power Solutions is a renowned provider of in situ crankshaft grinding services, offering a wide range of solutions for the marine, industrial, and power generation sectors. With a team of experienced technicians and state-of-the-art equipment, RA Power Solutions has earned a reputation for delivering high-quality, cost-effective crankshaft repair services.

In conclusion, in situ crankshaft grinding by RA Power Solutions is a cost-effective, efficient, and environmentally friendly solution for repairing damaged crankshafts. By eliminating the need for engine dismantling and transportation, this innovative process reduces downtime and costs, ensuring that engines are back up and running in no time.

For more information on crankshaft grinding, in situ crankshaft grinding machining, crankshaft grinding machine, and In situ grinding of crankshaft email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

Source URL: https://medium.com/@crankshaftgrindingmachine2/in-situ-crankshaft-grinding-a-cost-effective-solution-by-ra-power-solutions-crankshaft-grinding-5a8f420d74f5

Comments

Post a Comment